Introduction

The M542 is a high performance microstepping driver based on pure-sinusoidal currentcontrol technology. Owing to the above technology and the self-adjustment technology (self-adjust current control parameters) according to different motors, the driven motors can run with smaller noise, lower heating, smoother movement and have better performances at higher speed than most of the drivers in the markets. It is suitable for driving 2-phase and 4-phase hybrid stepping motors.

Features

l High performance, cost-effective

l Supply voltage up to 50DC

l Output current up to 4.5A

l Self-adjustment technology

l Pure-sinusoidal current control technology

l Pulse input frequency up to 300 KHz

l TTL compatible and optically isolated input

l Automatic idle-current reduction

l 16 selectable resolutions in decimal and binary, up to 51,200 steps/rev

l Suitable for 2-phase and 4-phase motors

l Support PUL/DIR and CW/CCW modes

l Short-voltage, over-voltage, over-current and short-cicuit protection

Applications

Suitable for a wide range of stepping motors, from NEMA size 17 to 34. It can be used in various kinds of machines, such as X-Y tables, labeling machines, laser cutters, engraving machines, pick-place devices, and so on. Particularly adapt to the applications desired with low noise, low heating, high speed performance.

2. Specifications

Electrical Specifications (Tj = 25Ōäā/77Ōäē)

|

Parameters |

M542 |

|

Min |

Typical |

Max |

Unit |

|

Output current |

1 |

- |

4.5(3 RMS) |

A |

|

Supply voltage |

+20 |

+36 |

+50 |

VDC |

|

Logic signal current |

7 |

10 |

16 |

mA |

|

Pulse input frequency |

0 |

- |

300 |

KHz |

|

Isolation resistance |

500 |

|

|

MΩ |

Operating Environment and other Specifications

|

Cooling |

Natural Cooling or Forced cooling |

|

Operating Environment |

Environment |

Avoid dust, oil fog and corrosive gases |

|

Ambient Temperature |

0 Ōäā’╝Ź 50Ōäā (32Ōäē ’╝Ź 122Ōäē) |

|

Humidity |

40%RH ’╝Ź 90%RH |

|

Operating Temperature |

70Ōäā (158Ōäē) Max |

|

Vibration |

5.9m/s2 Max |

|

Storage Temperature |

-20 Ōäā ’╝Ź 65Ōäā (-4Ōäē ’╝Ź 149Ōäē) |

|

Weight |

Approx. 290g |

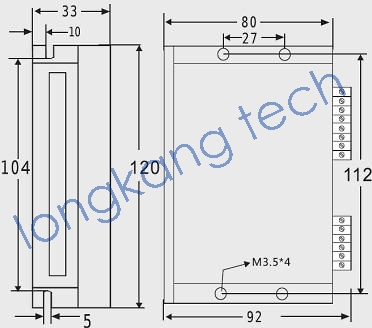

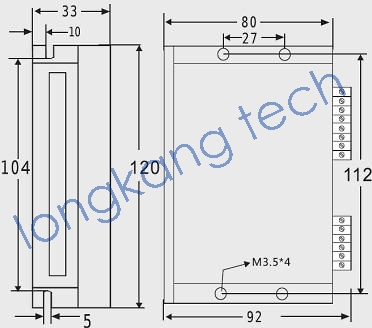

Mechanical Specifications (unit: mm)

Figure 1: Mechanical specifications

*Recommend use side mounting for better heat dissipationElimination of Heat

l Driver’s reliable working temperature should be <70Ōäā(158Ōäē), and motor working temperature should be <80Ōäā(176Ōäē);

l It is recommended to use automatic idle-current mode, namely current automatically reduce to 60% when motor stops, so as to reduce driver heating and motor heating;

l It is recommended to mount the driver vertically to maximize heat sink area. Use forced coolingmethod to cool the system if necessary.

3. Pin Assignment and Description

The M542 has two connectors, connector P1 for control signals connections, and connector P2 for power and motor connections. The following tables are brief descriptions of the two connectors. More detailed descriptions of the pins and related issues are presented in section 4, 5, 9.

Connector P1 Configurations

|

Pin Function |

Details |

|

PUL+ |

Pulsesignal: In single pulse (pulse/direction) mode, this input represents pulsesignal; 4-5Vwhen PUL-HIGH, 0-0.5V when PUL-LOW. In double pulse mode(pulse/pulse) , this input represents clockwise (CW) pulse’╝īactive at high levelor lowlevel (set by inside jumper J1 & J2). For reliable response, pulse widthshould be longer than 1.5μs. Series connect resistors for current-limiting when+12V or +24V used. The same as DIR and ENA signals. |

|

PUL- |

|

DIR+ |

DIRsignal: In single-pulse mode, this signal has low/high voltage levels,representing two directions of motor rotation; in double-pulse mode (set byinside jumper J1& J2), this signal is counter-clock (CCW) puls. For reliable motion response, DIRsignal should be ahead of PUL signal by 5μs at least. 4-5V when DIR-HIGH,0-0.5V when DIR-LOW. Please note that motion direction is also related tomotor-driver wiring match. Exchanging the connection of two wires for a coilto the driver will reverse motion direction. |

|

DIR- |

|

ENA+ |

Enablesignal: This signal is used for enabling/disabling the driver. High level(NPN control signal, PNP and Differential control signals are on the contrary,namely Low level for enabling.) for enabling the driver and low level fordisabling the driver. Usually left UNCONNECTED (ENABLED) |

|

ENA- |

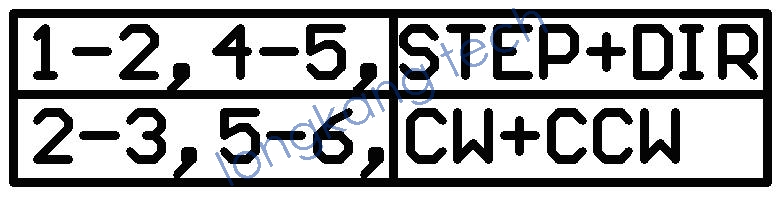

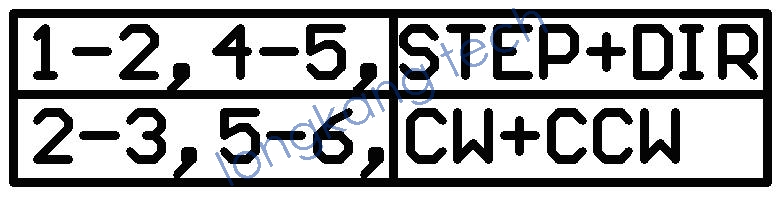

Selecting Control Signal Mode

There is a jumper J1 inside the M542 specifically for selecting control signal mode, as shown in figure 2. Default setting is PUL/DIR mode.

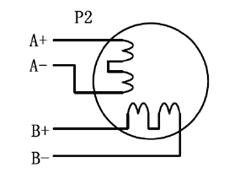

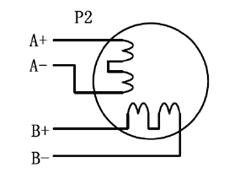

Connector P2 Configurations

Connector P2 Configurations

|

Pin Function |

Details |

|

DC+ |

Power supply, 20~50 VDC, Including voltage fluctuation and EMF voltage. |

|

DC- |

|

A+, A- |

Motor Phase A |

|

B+, B- |

Motor Phase B |

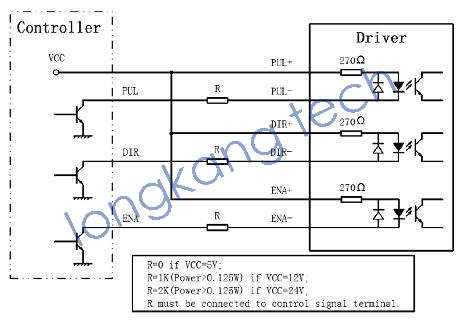

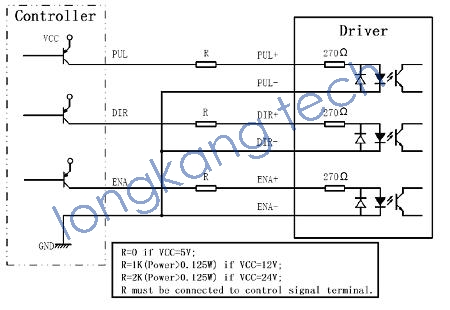

4. Control Signal Connector (P1) Interface

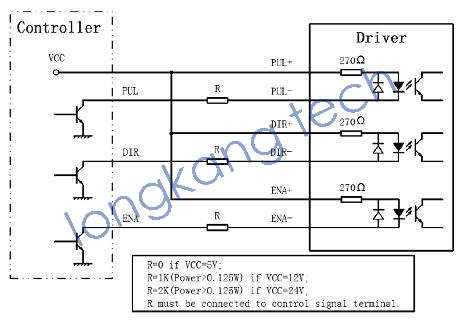

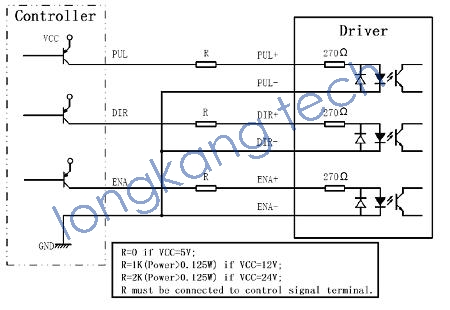

The M542 can accept differential and single-ended inputs (including open-collector and PNP output). The M542 has 3 optically isolated logic inputs which are located on connector P1 to accept line driver control signals. These inputs are isolated to minimize or eliminate electrical noises coupled onto the drive control signals. Recommend use line driver control signals to increase noise immunity of the driver in interference environments. In the following figures, connections to open-collector and PNP signals are illustrated.

Figure 3: Connections to open-collector signal (common-anode)

Figure 4: Connection to PNP signal (common-cathode)

5. Connecting the Motor

The M542 can drive any 2-pahse and 4-pahse hybrid stepping motors.

Connections to 4-lead Motors

4 lead motors are the least flexible but easiest to wire. Speed and torque will depend on winding inductance. In setting the driver output current, multiply the specified phase current by 1.4 todetermine the peak output current.

Connections to 6-lead Motors

Connections to 6-lead Motors

Like 8 lead stepping motors, 6 lead motors have two configurations available for high speed or hightorque operation. The higher speed configuration, or half coil, is so described because it uses one half of the motor’s inductor windings. The higher torque configuration, or full coil, uses the full windings of the phases.

Half Coil Configurations

As previously stated, the half coil configuration uses 50% of the motor phase windings. This gives lower inductance, hence, lower torque output. Like the parallel connection of 8 lead motor, the torque output will be more stable at higher speeds. This configuration is also referred to as half chopper. In setting the driver output current multiply the specified per phase (or unipolar) current rating by 1.4 to determine the peak output current.